1

/

of

2

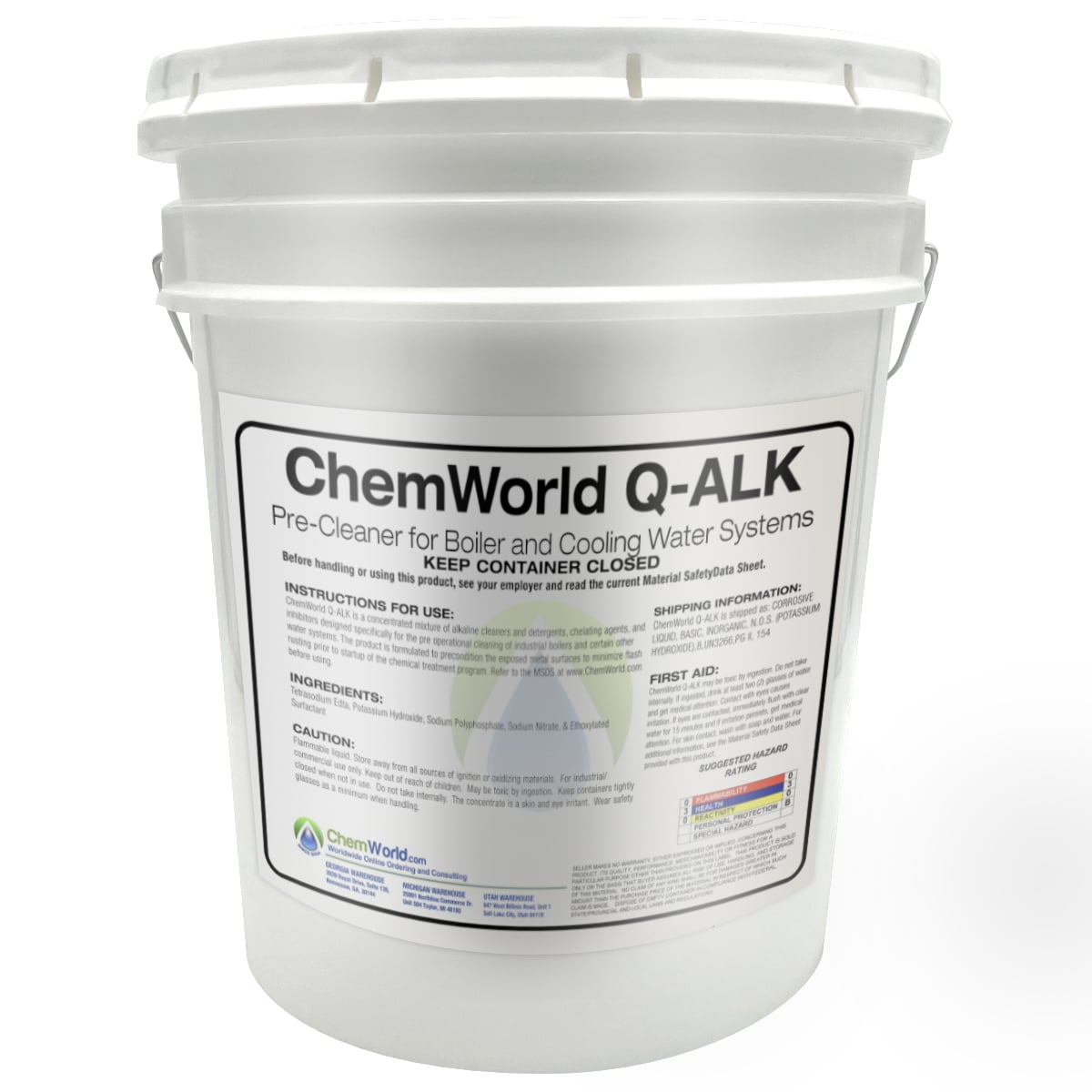

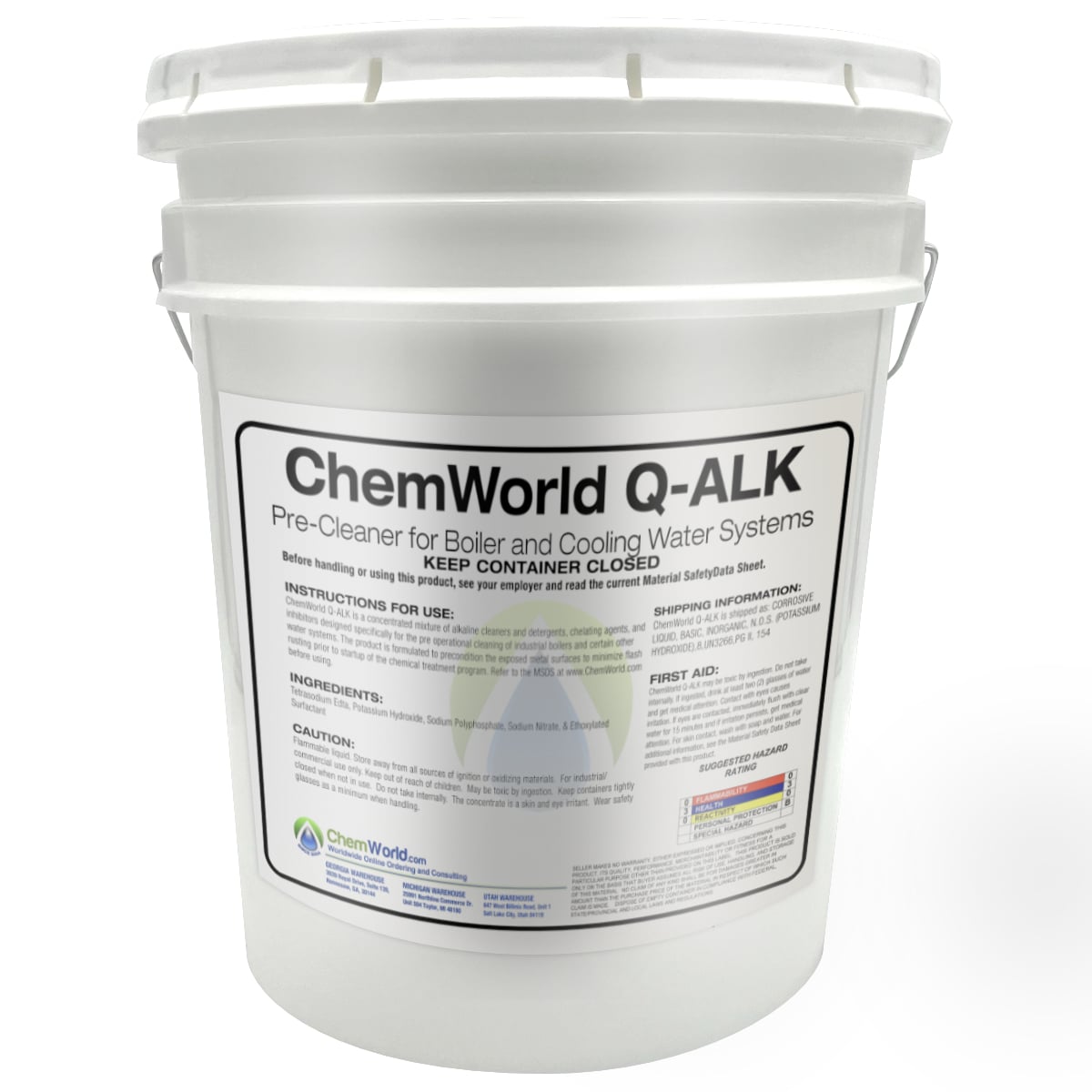

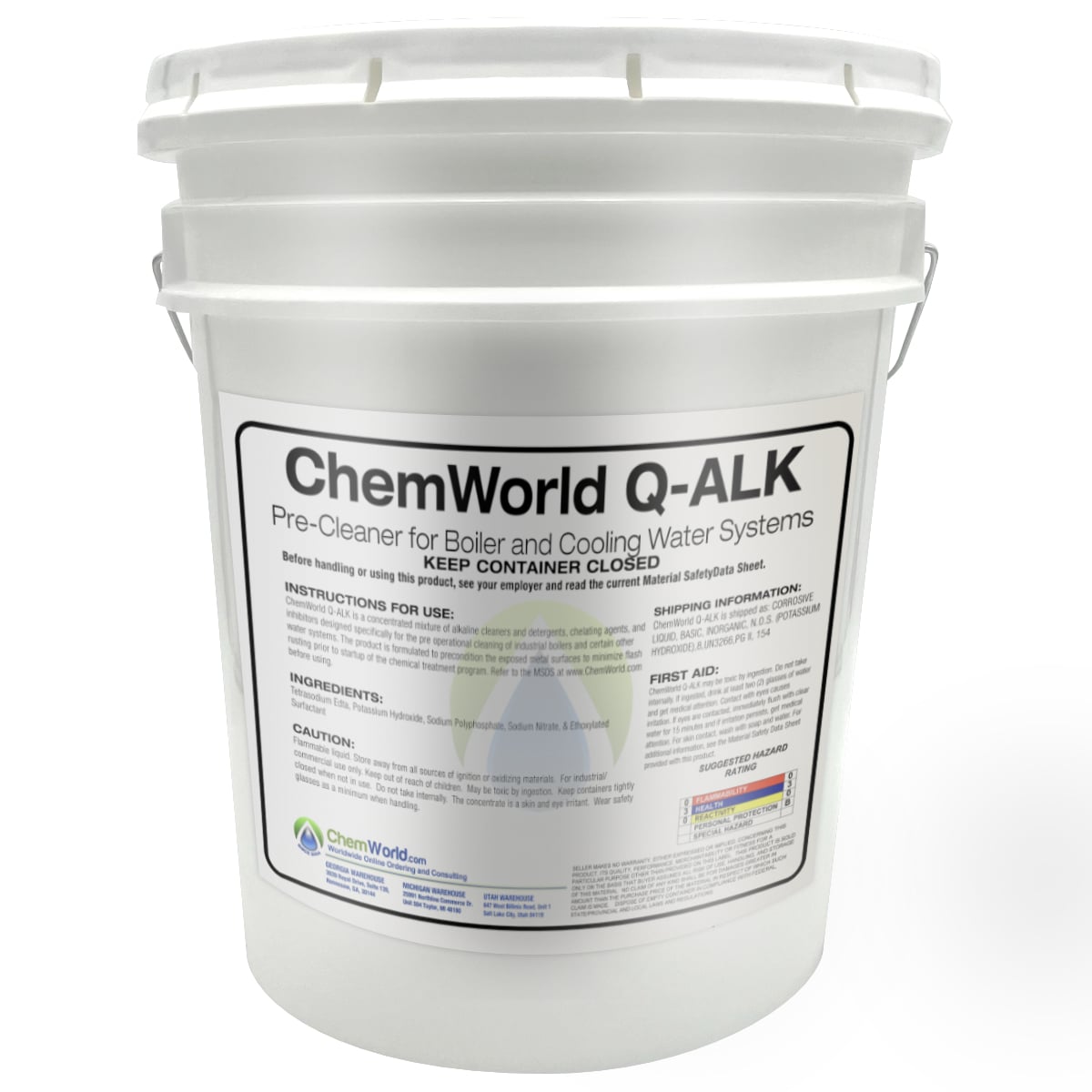

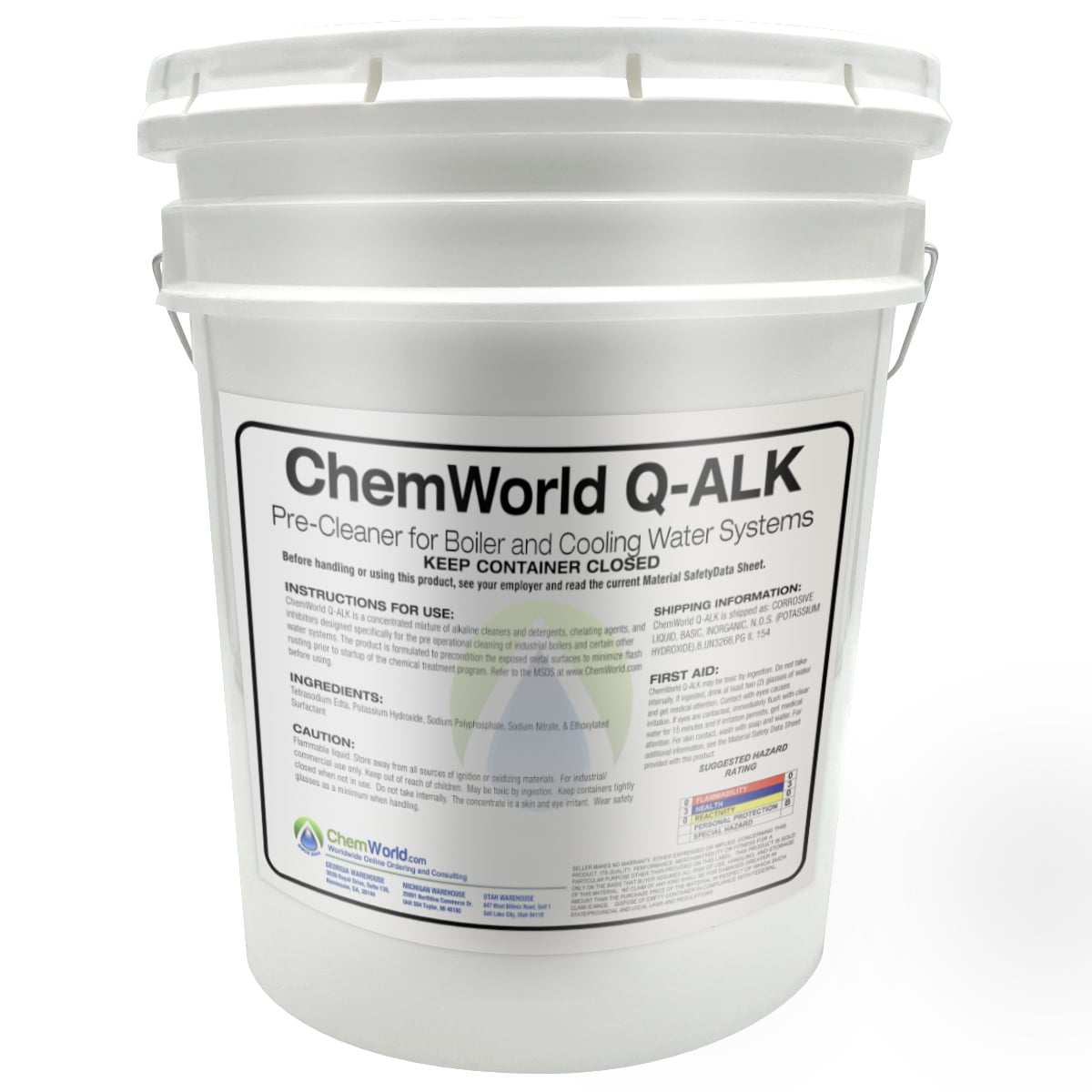

Boiler Out Chemical

Boiler Out Chemical

Regular price

$329.99 USD

Regular price

$399.99 USD

Sale price

$329.99 USD

Unit price

/

per

Couldn't load pickup availability

Boiler Boil Out

What is a boiler boil out chemical?A "Boiler Boil Out" is a concentrated mixture of alkaline cleaners and detergents, chelating agents, and inhibitors designed specifically for the pre-operating cleaning of industrial boilers and certain other water systems. The product is formulated to precondition the exposed metal surfaces to minimize flash rusting prior to start-up of the chemical treatment program. Order your ChemWorld Boiler Boil Out Q-ALK-BC online today.

How much chemical do I need to perform boiler boil out?

Depending on the condition of the boiler 1 to 4 gals are required per 100 gallons of water. Use a pH Test Strip to verify the water pH after injecting the chemical.

When should I perform a boiler boil out?

Every new boiler must have a boil out performed. Some companies choose to boil out the boiler every season.

How do I prepare for a boiler boil out?

Prior to any cleaning operation, the boiler should be opened and inspected to determine the cleanliness of internal surfaces and to insure that any rags, tools, etc. inadvertently left by workmen have been removed. Temporary gauge glasses should be installed and then all bottom drains should be closed and manhole covers replaced (except where a top opening is to be used for adding the cleaning chemicals and filling the unit). The steam valve from the unit must be closed and the vent(s) opened.

How do I perform a boiler boil out?

Once the unit is prepared, the prescribed cleaning chemicals should be added and the boiler filled with water to the top of the gauge glass. Where dry chemicals are used, they must be dissolved in a mixing tank prior to addition to the unit. The boiler should then be fired on low fire to obtain mixing and circulation. When steam is flowing freely from the vent(s), they are then closed and the pressure raised to 50% of the operating pressure (except for boilers operated at 15 psig or lower where the pressure may be raised to operating pressure). The pressure should then be maintained for 12-36 hours and during this period, the boiler should be blown down from the bottom by one-half of the gauge glass every two hours, refilling to the top of the glass after each blowdown.

After the boil out procedure is completed, the boiler should be carefully cooled. When sufficiently cool, the vent(s) may the be opened and the unit drained and thoroughly flushed with a high-pressure hose. After flushing, it should then be carefully inspected to insure the cleaning has been complete. Where severe deposits existed initially, it may be necessary to repeat the boil out to obtain proper results.

The boiler should then be closed and put in service or placed in wet or dry lay-up. Lay-up should be done according to proper procedures when the unit is to be stored for any appreciable period of time. A proper Boiler Boil Out procedure is important.

What chemicals do I use for a boiler boil out?

Our Boil Out product, is a proprietary formulation specifically recommended for boil-out of boilers. Our "Boil Out" contains a mixture of surfactants, caustic, phosphate, chelating agents (for mill scale removal), and an embrittlement inhibitor.

Share